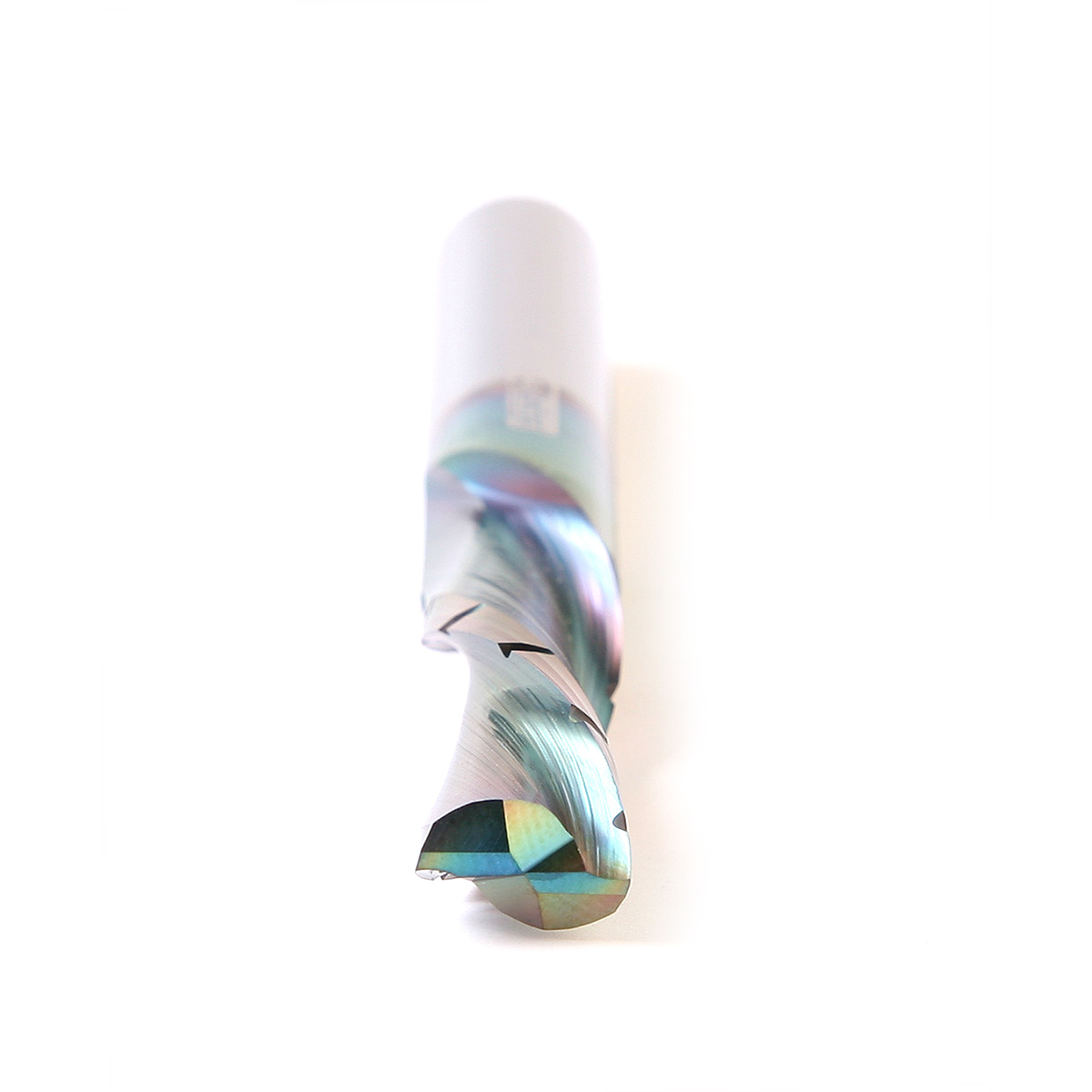

*AstraHP Coated* Bits&Bits 330-DNC375CB – 3/8″ Down-Cut Chip Breaker

$77.99

3/8″ Spiral Down-Cut bit offers sharp edges, perfect for shallow dadoes and grooves.

- AstraHP Coated

- Solid Carbide

- 3/8″ cutting diameter

- 3/8″ shank

- 1-1/4″ length of cut.

- 3-1/2” overall length.

- Made in USA

In stock

3/8″ x 3-1/2” Solid Carbide Flat End Mill with a .375 (3/8″) cutting tip and a 1-1/4″ length of cut.

Our spiral down-cut bits provide a shear cutting edge that leaves a smoother cut than standard router bits. Down cut spiral design provides sharp edges and flat bottoms with minimal chip out. These tools are coated with a proprietary high performance *Astra coating* that allows higher speed & feed rates as well as extended tool life & increased lubricity in abrasive material.

How Chipbreaker Bits Work:

Chipbreaker bits feature unique notch profiles, creating a serrated cutting edge, these notches break down chips into small, manageable pieces during the machining process. This type of geometry can boost your efficiency by minimizing machine downtime to clear large chips from the workpiece, improve bit life by minimizing the cutting force on the bit during machining, and allow for more accelerated speeds and feeds.

As a chipbreaker bit rotates and its cutting edge impacts the workpiece, material is sheared off from a part, creating chips. When that cutting process is interrupted, as is the case with chipbreakers in the cutting portion of the bit, chips become smaller in length and are easier to evacuate. Because the chipbreaker notches are offset flute-to-flute, a proper, flat surface finish is achieved as each flute cleans up any excess material left behind from previously passed flutes.

What is a DownCut bit?

With a DownCut bit, the advantage is that it’s pushing down on the piece you’re working on, plus it cleanly cuts the top surface. The tradeoff is the waste is pushed back into the cut area instead of being ejected, so we recommend not to cut dados or drill holes with a downcut. These bits are also made to be used slower – both in revolution or RPM of the bit, and also in spindle movement. That’s because the waste often has nowhere to go, so it is continually being chopped by the sharp flutes.

Made in the USA by Bits & Bits.

| Weight | .165 lbs |

|---|---|

| Brand | Bits & Bits |

| Shank | 3/8" |

| Cut Diameter | 3/8" (.375") |

| Cut Length | 1-1/4" |

| Cut Style | Down Cut |

| Overall Length | 3" |

Reviews

There are no reviews yet.