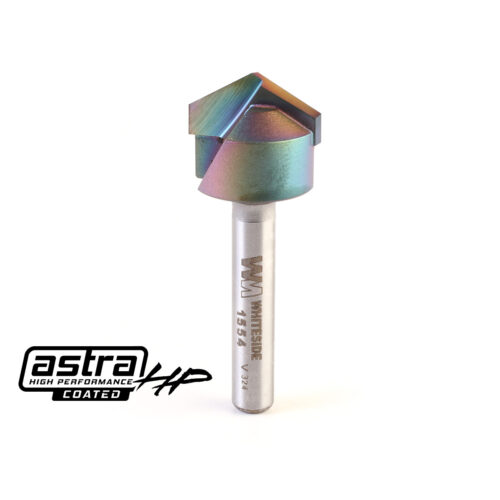

Astra Coating Info

How does AstraHP Coating extend the life of your bits?

During any type of cutting process, the cutting bit endures heat generated by the friction and abrasion of the bit moving through the material. This friction and abrasion are significant contributors to bit wear, leading to the dulling or degradation of the cutting edge, which in turn results in burning, a rough finish, and vibration.

AstraHP Coating is a multi-layered surface coating applied to our cutting tools that effectively reduces the friction coefficient of the bit. This reduction in friction enables smoother and faster cutting while minimizing heat generated from friction. Consequently, AstraHP Coating significantly extends the lifespan of the cutting tool. It is exceptionally effective across a range of materials, including wood, metals, aluminum, brass, and plastics, allowing for increased speed and feed rates. AstraHP Coating also helps in reducing the accumulation of dust and pitch. In the event that buildup does occur, the bit can be easily cleaned using a bit cleaning solution or compatible solvents due to its chemical resistance.

It is inevitable that a cutting tool will eventually wear to a point where it requires sharpening. AstraHP Coated tools can be sharpened in the same manner as standard carbide tools, ensuring they maintain a sharp cutting edge for extended usability.

*AstraHP Coated* Bits&Bits 425-SRF375 - 3/8" Spiral Up Cut CNC Router Bit - 1/4" Shank

*AstraHP Coated* Bits&Bits 425-SRF375 - 3/8" Spiral Up Cut CNC Router Bit - 1/4" Shank