WHY SPIRAL ROUTER BITS?

Standard 2 flute straight router bits contact your workpiece two times per revolution. This causes excessive vibration and potentially lots of tearout, even losing large chunks when transitioning from edge grain to end grain. Spiral flush trim router bits are designed to shear the wood and are constantly in contact with your workpiece all 360 degrees of revolution, causing no vibration and smoother cuts. This cutting action leaves a smooth surface without any vertical ridges.

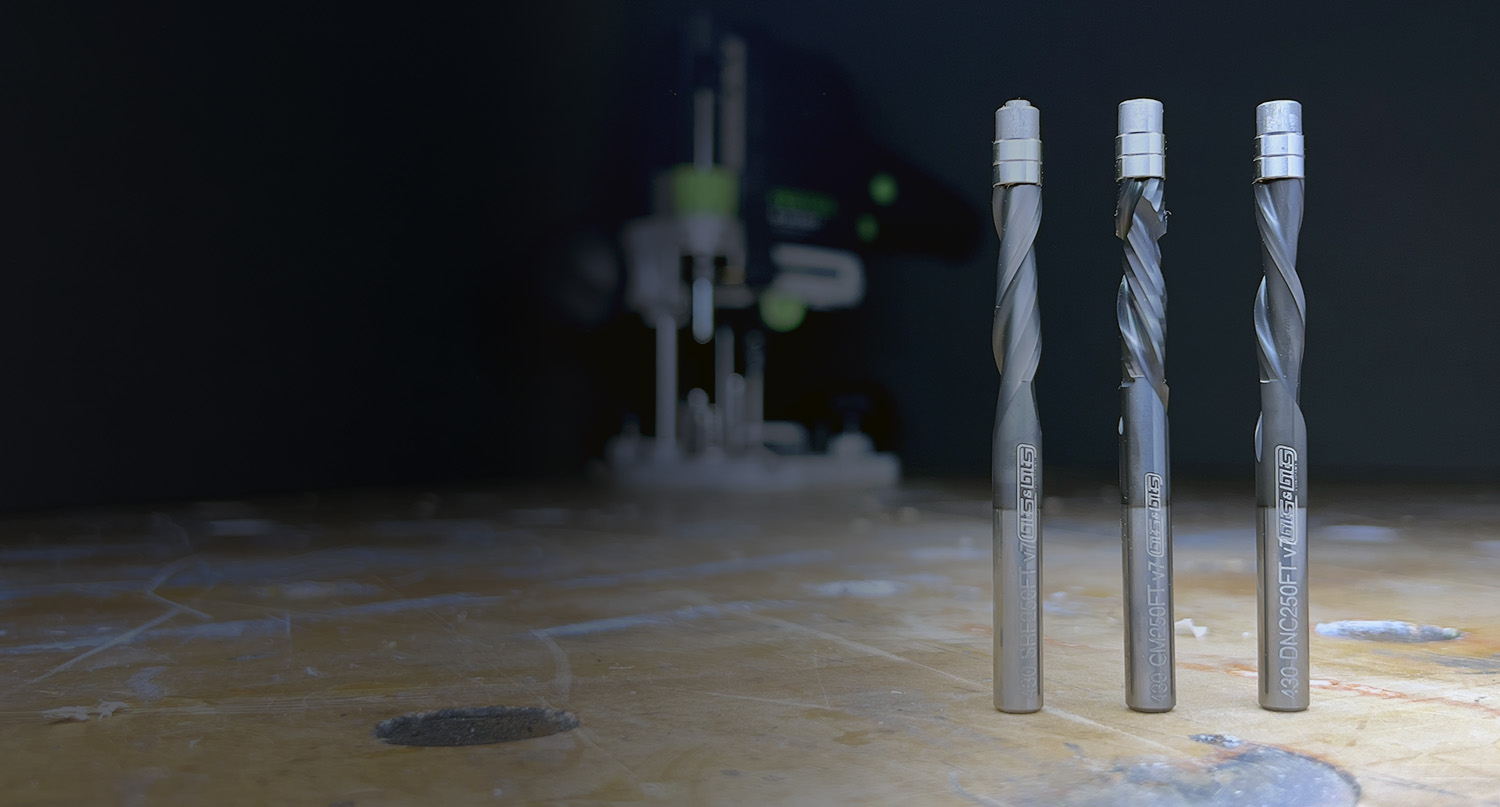

WHAT IS FLUTE DIRECTION?

Bits & Bits *Astra Coated* Spiral flush trim bits are available in three flute directions; up-cut, down-cut and compression. Direction is always in relation to the router; an up-cut spiral is pulling chips up towards the router. Down-cut spirals push chips down and away from the router. A compression bit is the best of both bits, with up-cut flutes at the tip next to the bearings and the down-cut flutes closest to the router. This effectively pulls the wood fibers towards the center of the wood being trimmed and reduces tearout or ‘fuzz’ along the top and bottom edge of your workpiece. Keep in mind when the router is upside down in a router table, the directions will reverse with a down-cut pushing chips up away from the router.